The construction industry accounts for nearly 1 in 5 workplace fatalities. In a field where safety is the difference between ordinary routine and injury, every precaution must be taken to mitigate risks—because jobsite accidents are preventable.

Providing personal protective equipment (PPE) is a critical measure that protects workers from construction hazards. From helmets and gloves to high-visibility clothing, the right gear doesn't just enhance safety; it protects the bottom line by keeping you compliant with Occupational Safety and Health Administration (OSHA) guidelines. Violations can lead to thousands of dollars in fines and—especially in the case of an accident—costly lawsuits that put your company at fault.

So, what PPE do you actually need to provide for your team members? This article will present you with a checklist of eight OSHA-required essentials for construction firms, as well as three nice-to-haves.

9 Types of OSHA-Required Construction PPE

The exact PPE you’re required to provide can depend on jobsite conditions and the equipment each employee will use on the job. However, most equipment will fall under the following nine categories.

As you purchase and distribute essential items, keep in mind that OSHA requires protective gear to fit well—and your employees must understand how to properly adjust, use, maintain, and dispose of each item as needed.

1. Head protection

Head injuries are undoubtedly among the most dangerous incidents in the construction field. According to OSHA, companies must provide helmets that protect against dangers like:

- Falling or flying objects

- Head injuries from fixed objects or falls

- Electrical shocks or burns

Effective head protection should prevent penetration, absorb any impact or shock, and be properly secured. Depending on the role, water- and burn-resistant head protection may be essential.

2. Eye & Face Protection

Skilled trade jobs like welding, sheet metal repair, and general construction labor can expose workers to many foreign particles and dangerous substances. In fact, working outside alone can increase the risk of dust entering the eyes or objects flying due to strong winds.

OSHA requires construction firms to provide snug eye and face protection that defends against the hazards involved in each role, whether it be wood chips, molten metal, or light radiation. The right PPE may include:

- Safety goggles

- Welding shields

- Safety spectacles

Prescription lenses—or PPE that fits over prescription glasses—are expected for employees with vision impairments.

3. Hearing Protection

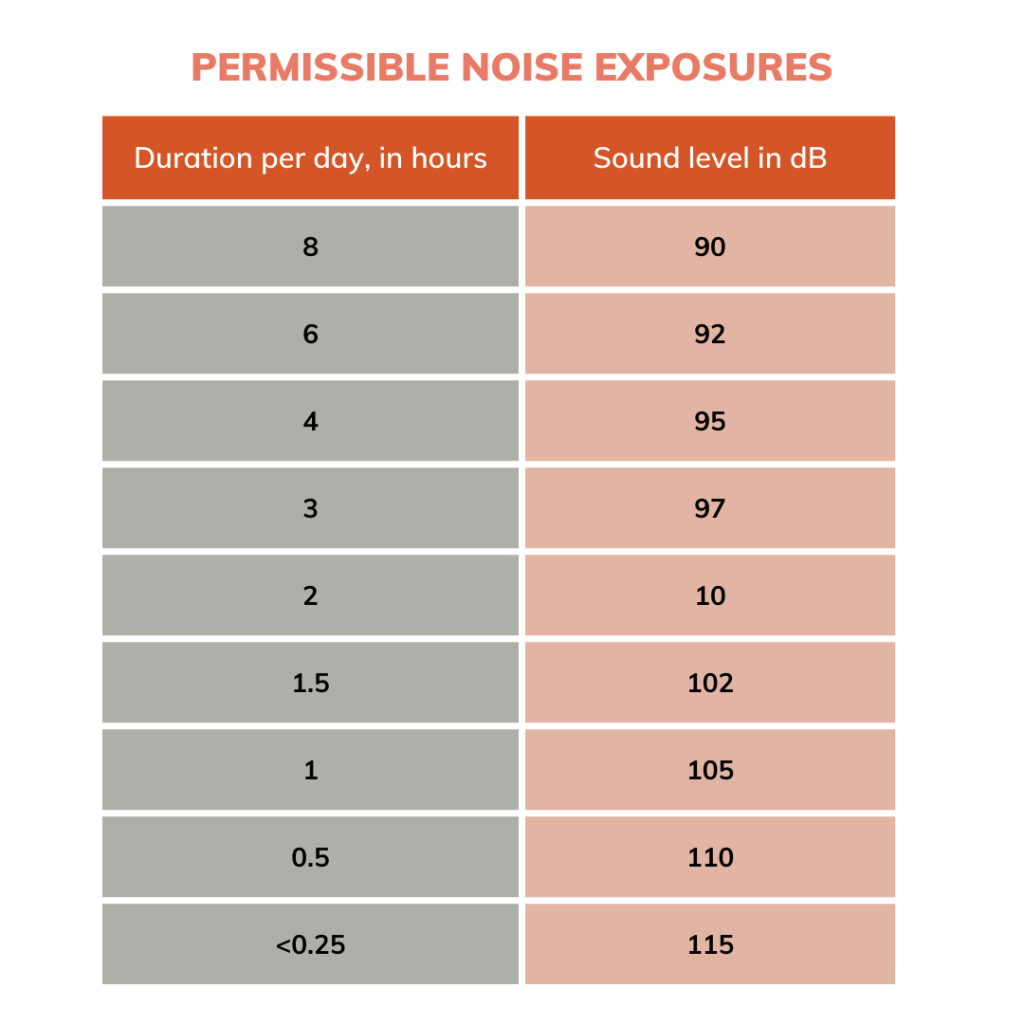

Construction sites aren’t exactly quiet places. In some cases, they can be deafening without ear protection. When noise can’t be reduced below safe exposure levels, as indicated below, PPE must be provided to preserve employee hearing.

Permissible hearing protection may include:

- Self-forming, single-use earplugs made of fiberglass wool, foam, silicone rubber, or waxed cotton

- Pre-formed or molded earplugs that are individually fitted

- Earmuffs that seal well around the ear

4. Respiratory Protection

Inhaling foreign materials can be just as dangerous as an external injury on the jobsite. When your construction workers may be exposed to harmful sprays, fumes, gases, or significant dust, respiratory protection is expected. This is especially the case if employees work in low-ventilation areas. Depending on the severity, dust masks or respirators may be optimal.

5. Body Protection

Most construction workers need some form of body protection due to consistent exposure to sharp tools and heavy machinery. Providing PPE such as coveralls, vests, and jackets is standard for most firms. However, some roles may additionally require fireproof or chemical-resistant clothing.

6. Foot Protection

Thorough body protection should always include foot protection. Workers may be exposed to falling objects, including sharp or heavy objects that can cause injury, or liquids that can cause slips or seep in through basic shoes. Preventing accidents requires sturdy foot protection such as steel-toed boots and metatarsal guards.

If workers may be exposed to electrical hazards, non-conducive materials are essential.

7. Fall Protection

Fatal falls, slips, and trips are particularly common in the construction industry, which accounts for nearly half of all these workplace incidents. On top of required safety systems—including appropriate guardrails and safety nets—construction firms need to provide personal fall arrest systems where applicable. This PPE may include:

- Body belts

- Harnesses

- Non-locking snaphooks

- Lanyards

- Vertical lifelines

8. Specialized PPE

Some essential PPE may be specific to a particular task or machinery. For example, tradespeople who may be working with hazardous materials—for instance, during a renovation that involves asbestos removal or a pipefitting project that deals with chemical waste—workers will need specialized gear to ensure full protection.

Be sure to review the unique demands of each role as you build out your construction PPE checklist.

3 Types of Construction Gear to Supplement Worker Safety

Following OSHA requirements is the bare minimum you can do to enhance worker protections. As construction companies move toward a safety-first culture, many industry leaders are also providing supplementary PPE to prevent accidents. Here are three types of gear you can consider.

1. Cooling Products

The recently proposed OSHA heat standard shows regulators are cracking down on improper protections during the summer. When the weather is hot—or when workplace conditions are warm—employees can benefit from products such as heat-reflective clothing, vests with icepacks, and cooling neck wraps.

2. High-Quality Apparel

It’s easy to purchase gear that meets OSHA recommendations—but investing in top-quality apparel with premium features can further optimize worker safety. When selecting clothing, consider features like:

- Ultraviolet Protection Factor (UPF)

- Moisture-wicking fabric

- Cut-resistant materials (like polyethylene fiber)

3. Construction Exoskeleton

Exoskeletons are an exciting new construction technology that serves a dual purpose: protecting workers and increasing productivity. With this wearable support, which amplifies capabilities (sometimes with electric power), tradespeople experience less fatigue and lower injury risk. All the while, they can carry heavier loads and complete manual tasks faster.

Gear up Your Construction Team with Complimentary PPE

OSHA requirements are continually evolving, and keeping track of your construction PPE obligations can be a time-consuming task. However, an experienced skilled trades staffing firm can help you shoulder the burden and provide the industry knowledge required to reduce your risk.

Prior to each placement, Skinner provides protective gear deemed mandatory by OSHA. Additionally, we give employees a $100 voucher for new safety boots and a free safety coat after one year with our team. But our commitment to your temporary worker safety goes beyond supplying PPE. Our firm also ensures workers are up to date on safety training and takes care of workers’ compensation so you can focus on your project with peace of mind.

Elevate your safety culture with comprehensive staffing support. Get connected with Skinner today.

Related Articles:

3 Ways to Avoid Construction Worker Misclassification & Stay Compliant

Are Construction Workers Happy? How to Boost Employee Satisfaction & Improve Your Bottom Line

Bridging the Language Gap: How to Overcome Language Barriers in Your Construction Workforce